Biogas plants generate liquid digestate. The larger the plant, the more digestate is produced – and it all needs to go somewhere. Our solution: process the liquid digestate into fertiliser granules and sell them!

Challenge: Storing and spreading liquid digestate

Large biogas plants in particular often face the challenge of having to store liquid digestate before it can be spread on distant fields, because there is not enough farmland available nearby for application. This can involve considerable effort and high costs.

Solution: Drying liquid digestate

With a dry matter content of just four to six per cent, liquid digestate consists mainly of water. The more water that can be removed from the digestate, the easier storage and transport become.

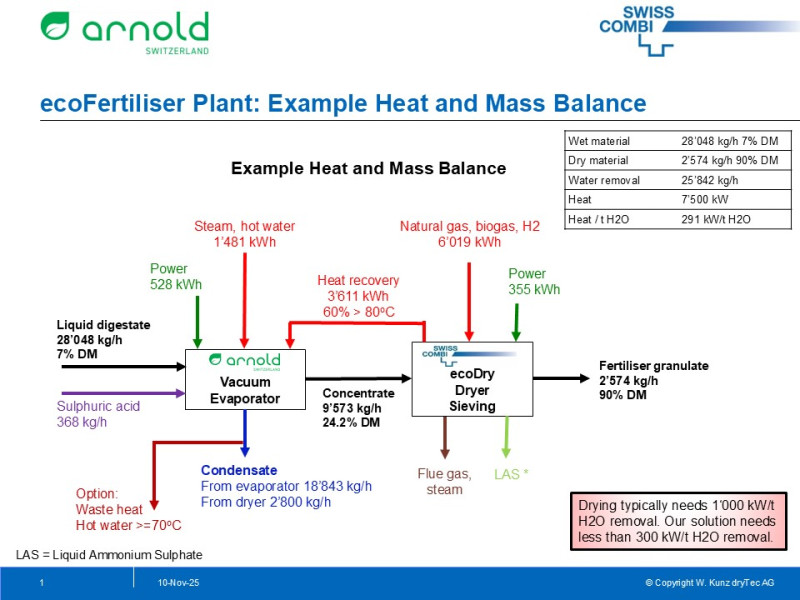

For this reason, SWISS COMBI, together with Arnold + Partner, has developed a process to turn liquid digestate into a free-flowing, storable organic fertiliser granulate: the ecoFertiliser Plant (eFP).

Processing liquid digestate into fertiliser granules takes place in two main steps:

Step 1: Concentrating the liquid digestate

First, the digestate is concentrated in the vacuum evaporator from Arnold + Partner to a creamy concentrate with a dry matter content of 15 to 25 per cent. The evaporator uses the waste heat of the ecoDry drum dryer, which is used in the second step – an important contribution to the energy efficiency of the eFP.

Step 2: Drying the digestate into fertiliser granules

In the second step, the digestate concentrate is dried into granules in the ecoDry drum dryer and can then be used as an organic fertiliser.

The advantages of granules compared with liquid digestate are clear:

Reduced volume

Easier storage

Lower storage and transport costs

More precise dosing

Plant-specific nutrient composition possible

Lower greenhouse gas emissions

Additional source of revenue

How the ecoFertiliser Plant works

How liquid digestate is transformed into a concentrate and then into fertiliser granules in practice is demonstrated here using the test plant at our site:

Drying liquid digestate into fertiliser granules in our test plant

Energy-efficient drying

In the eFP, around 28 tonnes of liquid digestate are processed into almost 2.6 tonnes of fertiliser granules per hour. And with a heat demand of less than 300 kW per tonne of water removed, our solution is significantly more efficient than conventional drying methods, which require more than three times as much heat for water evaporation.

If you would like to learn more about the ecoFertiliser Plant, please feel free to contact us!