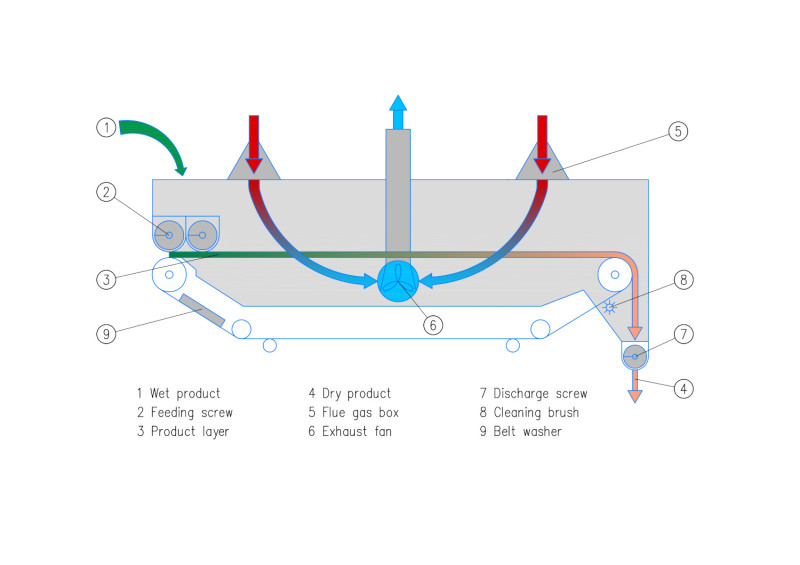

The SWISS COMBI KUVO is a belt dryer specially designed for the utilisation of hot process air or flue gas from a drum dryer or boiler. The process air or flue gas is cooled down and then passed through the product layer in the KUVO. The product layer thus serves as a dust filter and is pre-dried at the same time.

The SWISS COMBI KUVO is typically used when a product needs to be pre-dried in order to reduce energy consumption during the final drying process or to improve the combustibility of a fuel.

A typical application of the SWISS COMBI KUVO is the drying of wood chips in a drum dryer. The flue gas from the drum dryer is fed into a KUVO to pre-dry wood chips in it, thereby reducing the dust emissions from the drum dryer. In the drum dryer, the pre-dried chips are dried to completion.

Another possible application for the SWISS COMBI KUVO is the use of hot process air to dry alternative fuels such as combustible waste. This is done, for example, in the cement industry, where sufficient waste heat is generated during the cooling of the clinker to dry wet refuse-derived fuels (RDF) such as paper, wood, cardboard, plastic or textiles, which can then be used as a cost-effective fuel.

The SWISS COMBI KUVO is also often retrofitted when dust emissions generated during drying need to be reduced cost-effectively. In such cases, the layer of product being pre-dried also acts as a dust filter – provided the material to be dried is not intended for use as animal feed.